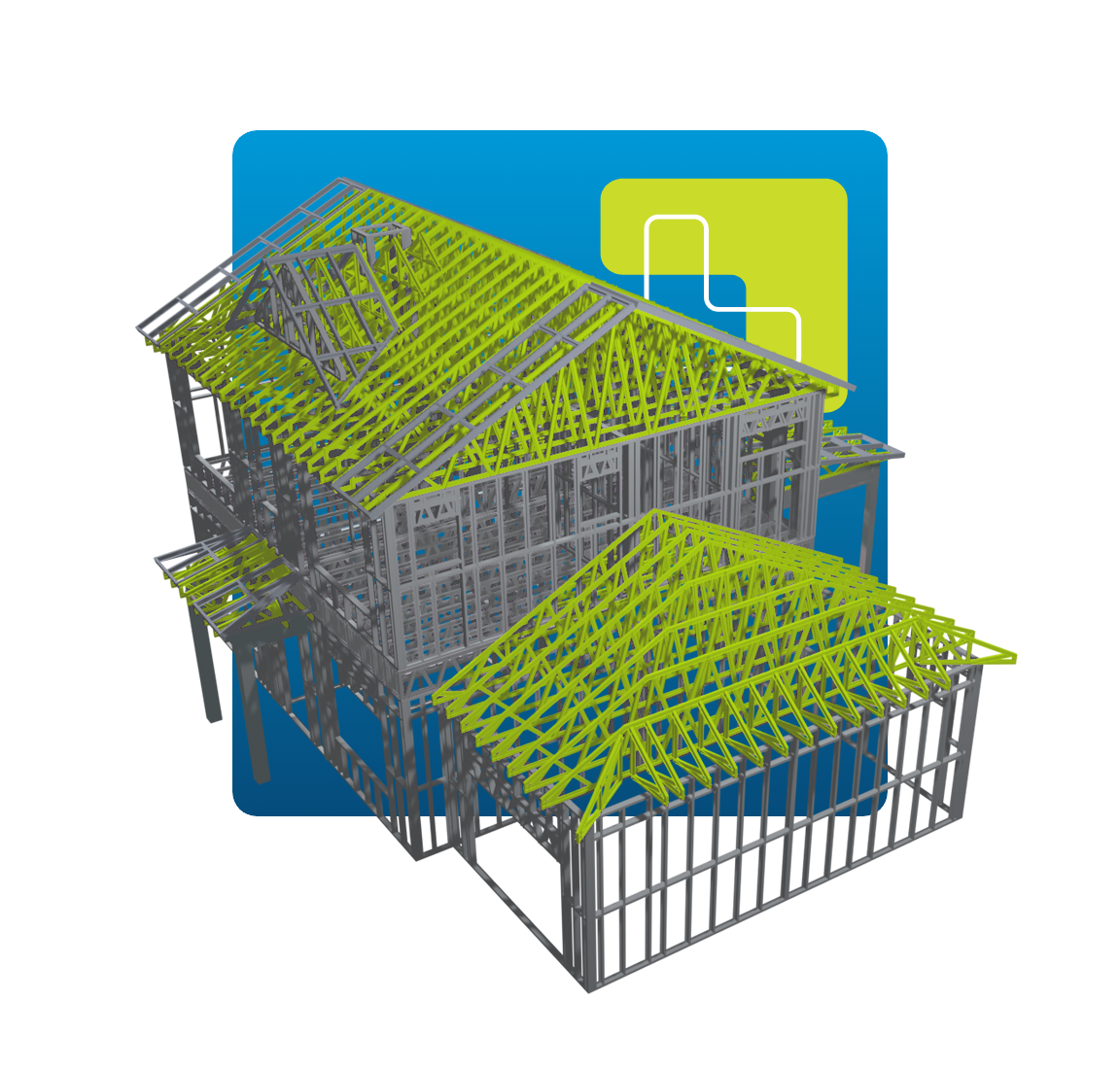

Light Gauge Residential or Commercial

Cold Formed Steel Trusses

More and more businesses taking on construction projects are switching from traditional wooden trusses to the far more durable and cost-effective cold formed steel trusses. This choice is often met with significantly shorter installation time and far less expense than previously expected in traditional truss installation processes. Cold formed steel is one of the best materials to use when looking for trusses that are strong and stable, and Modern Structural Systems offers the perfect steel truss option whether you would like to use non-combustible material for your construction, or because you’re looking for an enduring and ecologically friendly product for your construction project.

Pre-Engineered Trusses

Check out our full range of cold-formed steel trusses- LGS trusses designed for up to 150 mph winds

Light Gauge Steel Trusses

Trusses from Modern Structural Systems can come in a variety of styles, shapes, and sizes to best fit the needs of your build and gives you the optimal roofing shape that you are looking for.

There are many advantages of using cold formed steel trusses for your roofing trusses:

• Light gauge steel is capable of undertaking a great amount of stress without failing engineering codes, and can cover wider spans with less weight than wood.

• Its high strength to weight ratio allows it to handle distances like this with no problem and very little deflection.

There are 2 profiles available to construct your trusses:

• Bolted 2 inch “hat channel”

•Riveted 3.5 inch “C Channel”

The customizability of cold formed steel allows you to have the perfect length of trusses for any job with no issues.

Trusses made from cold formed steel have a variety of other advantages as well:

• They are lightweight yet incredibly durable so not only will installation be a relative breeze, but it will also remain up to snuff for long periods of time with low maintenance costs in both time and money.

• Cold formed steel is fireproof/incombustible.

• Is at no risk for problems like mildew and mold, resistant to termite infestations.

• It is significantly better at combating the elements than flimsier components like wood.

Types of open web trusses

Cold-formed steel trusses are versatile and can be designed and manufactured in various configurations to meet the structural and architectural requirements of a project. These trusses are lightweight, strong, and resistant to corrosion, making them an attractive choice for a wide range of applications. Here are some common types of trusses that can be designed and manufactured using cold-formed steel:

- Pratt Truss: A Pratt truss has vertical members in compression and diagonal members in tension. It is one of the most common truss types used for steel structures due to its efficient load distribution, adaptability to different span lengths, and ease of fabrication.

- Warren Truss: A Warren truss consists of alternating diagonal members forming a series of equilateral triangles. This type of truss is popular for its simplicity, efficient use of materials, and suitability for longer spans.

- Howe Truss: The Howe truss is similar to the Pratt truss, but the diagonal members are in compression and the vertical members are in tension. This configuration is less common than the Pratt truss but can be useful for specific loading conditions or design requirements.

- North Light Truss: A North Light truss is designed with a short vertical section and a longer sloping section, often used in industrial buildings to allow for natural lighting from the north. Cold-formed steel can be used to create these trusses, which are typically placed at regular intervals to create a sawtooth roof profile.

- Scissor Truss: Scissor trusses have a distinctive shape with two bottom chords intersecting at an interior point, creating a vaulted ceiling effect. They are commonly used in residential and commercial buildings where a more open or aesthetic ceiling is desired.

- Flat Truss: Flat trusses, also known as parallel chord trusses, consist of top and bottom chords running parallel to each other with vertical and diagonal web members. These trusses are often used in commercial and industrial applications where a flat roof is required.

- K-Truss: A K-truss is characterized by its K-shaped web members, which provide efficient load distribution and increased stability. This type of truss can be utilized in various applications, including bridges and long-span roof systems.

- Fink Truss: The Fink truss has a distinctive W-shape created by its web members, which efficiently distribute the loads to the top and bottom chords. This truss type is commonly used for longer spans in residential and commercial roof systems.

These are just a few examples of truss types that can be designed and manufactured using cold-formed steel. The versatility of cold-formed steel allows for the creation of custom truss configurations to meet specific project requirements, making it an ideal choice for various structural applications.

Custom Truss Designs Produced from your CAD files

Custom trusses designed with light gauge cold-formed steel offer architects and engineers new design capabilities and flexibility. Advanced computer-aided design (CAD) software and engineering tools have revolutionized the process of designing and manufacturing these trusses, making it possible to create unique, tailor-made solutions that meet specific project requirements.

Here’s how custom trusses can be designed using light gauge cold-formed steel and CAD software:

- Architectural design input: Architects can use CAD software to create a 3D model of their envisioned structure, incorporating the desired layout, aesthetics, and functional requirements. The software allows architects to explore various design possibilities and make adjustments as needed.

- Integration with structural engineering software: CAD models can be imported into specialized structural engineering software, where engineers can develop the truss design. This software helps engineers optimize the truss configuration, member sizes, and connections, ensuring the structure meets the required load-bearing capacity and performance criteria.

- Building Information Modeling (BIM) integration: BIM is an advanced 3D modeling technology that facilitates collaboration among architects, engineers, and other construction professionals. By incorporating cold-formed steel trusses into a BIM model, designers can visualize the entire building system, identify potential clashes or design issues, and optimize the overall design.

- Parametric modeling capabilities: Parametric modeling in CAD software enables designers to define relationships between various design elements, making it easier to explore and optimize custom truss designs. For example, changes in span length or load conditions can be automatically updated in the model, allowing engineers to quickly evaluate different design scenarios and find the most efficient solution.

- Computer-controlled manufacturing: Once the custom truss design is finalized, CAD files can be exported directly to computer-controlled manufacturing equipment. This seamless integration ensures that the trusses are produced with high precision and accuracy, resulting in improved quality and reduced waste.

- Prefabrication and just-in-time delivery: Light gauge cold-formed steel trusses can be prefabricated off-site in a controlled factory environment, improving the overall quality and reducing the on-site construction time. The trusses can be delivered to the job site on a just-in-time basis, reducing storage and handling requirements.

The combination of light gauge cold-formed steel and advanced CAD software has opened up new design capabilities for architects, enabling them to create custom trusses that are both efficient and visually appealing. This technology has streamlined the design and manufacturing process, resulting in higher-quality, more sustainable, and cost-effective building solutions.