Beginner’s Guide To Cold Formed Steel for Construction of Metal Buildings

What is it? How can I use it? Why should I use it?

Intro to Cold Formed Steel (CFS)

CFS certainly isn’t new material for metal buildings. Steel framing has been used in North America for over 100 years. Because of its light weight and durability, it can be used in many applications. Applications can include interior, non-loadbearing partition walls and structural members in mid-rise and multi-family buildings.

Whatever your current level of knowledge, consider this a primer on all things CFS framing. With Modern Structural Systems, you’ll learn what CFS is, how it can benefit a construction project, and the basics of designing and ordering CFS.

Tip: Before you get started, familiarize yourself with industry and technical terms related to cold formed steel framing by clicking here.

Why Should I Use Cold Formed Steel Framing?

CFS framing is lightweight, extremely strong, noncombustible, and relatively easy to install. Because of this, it has dominated the commercial construction market for interior, non-loadbearing partition walls. With advanced technological developments like panelized systems, the building community now uses CFS for all structural applications.

In today’s world, CFS framing has rapidly become the material of choice for student dormitories, assisted living facilities, and hotels across the country by developers interested in maximizing their ROI.

What is Cold Formed Steel?

CFS members are made from structural quality sheet steel. Then, it’s formed into C-sections and other shapes by roll-forming the steel through a series of dies. Additionally, no heat is required to form the shapes (unlike hot-rolled steel). Depending on your construction needs, a variety of steel thicknesses are available to meet a spectrum of structural and non-structural applications.

Value Benefits of Steel

As a construction material, cold formed steel has many advantages.

- It doesn’t shrink or split.

- Won’t absorb moisture.

- Resists warping, termites, and fire.

Quality

As a uniformly manufactured product, the quality of CFS is very consistent. That means less scrap to haul off because there is less waste — and all of it is recyclable. In addition to lowering scrap disposal expenses, the fire resistance of CFS framing can also help reduce project costs. This can be done through discounts on builders’ risk and other construction insurance requirements.

Strength & Ductility

CFS’s physical properties allow it to be used in a wide range of environments. For example, its strength and ductility make it ideal for construction in regions subject to high winds or earthquakes. A study conducted by the National Association of Home Builders (NAHB) Research Center showed the zinc coating on steel framing materials can protect against corrosion for hundreds of years.

Sustainability

Because each piece of CFS contains a minimum of 25% recyclable content, it is 100% recyclable at the end of its lifespan. In addition, it emits no volatile organic compounds — it’s an exceptionally sustainable building material.

On The Jobsite

CFS also provides numerous advantages in terms of the construction process itself.

CFS is light – making it easy to ship, handle and assemble. Additionally, greater strength means less material. For example, if a project calls for stick framing, the strength of cold formed steel allows it to be installed on 24” centers rather than traditional 16” centers. This means fewer studs to install.

As a construction material, CFS has many advantages including:

- It doesn’t shrink or split.

- Won’t absorb moisture.

- Resists warping, termites, and fire.

Quick & Easy Assembly

Because CFS is manufactured to exacting standards, it is ideally suited for manufacturing into panels and trusses. Due to it also being light in weight, it can be quickly and easily installed with fewer framers on the job. Some builders have found that ordering factory-manufactured steel panels and trusses is an ideal way to move into steel framing. This is because it minimizes the need for skilled framers, and provides access to experienced design and layout pros.

Accommodates Mechanical, Electrical, & Plumbing Installation

In addition to speeding up the framing process, CFS panels contain pre-punched holes. These holes are designed to quickly and easily accommodate mechanical, electric, and plumbing installation after framing, for instance.

Let's Get Rolling!

What to do before starting your next cold formed steel framing project

If you are getting ready to design CFS framed metal buildings, you’ve made a great choice for a resilient system. This is because CFS is proven to deliver years of quality performance. But where should you begin? Additionally, what are the steps to designing successfully with CFS framing? While there are many steps to doing it right, here are 6 of the most critical:

6 Critical Steps to Take Before Starting Your CFS Framed Project:

Let's Get Rolling!

Do you need to order CFS framing for your next metal building project —

but aren’t sure where to start?

When ordering CFS, you must first be aware of the different types of products and how they’re designated by manufacturers and distributors.

CFS Designator System

A wide variety of CFS member profiles, depths, widths, and material thicknesses exist. Due to this, the steel framing manufacturing industry has a standard designator system that all CFS manufacturers and suppliers use. Additionally, it is important to note that this system is also useful in identifying CFS framing in building codes. That said, understanding the designator system makes it easy to specify the right CFS components.

But wait! While it’s great to understand the designator system, we can make it easy for you. In order to get help, just send us your blueprints and we’ll spec the project for your approval.

The system is alpha-numeric. For example, a CFS member might have the designation 350S162-43. If you don’t have knowledge of the designation system, you can’t tell much from that number. This poses common questions like: Is it a stud? Track? U-channel? What about its thickness and other material dimensions? That said, once you understand the system, you can identify the member at a glance.

Identifying CFS Components

Normally these are the components you will find, denoted by the acronym STUFL. When working with MSS, we provide a modern approach to the manufacturing timeline. In doing this, we eliminate and streamline the process. For example, our studs are swaged at connections which then behave like a track. US building codes typically don’t require a Furring channel, and we achieve sufficient headers or lintels without the use of L-Headers.

Designator Letters Convey the Type of CFS Framing Member

There are five CFS profiles. To remember them, think of the acronym STUFL: stud, track, U-channel, furring channel, and L-headers.

S – STUDS (or joists, or rafters):

Studs include wall studs, joists, and rafters, all of which have the same shape. Additionally, all studs have returns or lips. Typical return sizes are ½” and ⅝”.

T – TRACK:

Use Track as the top and bottom plates of a CFS wall. You can also use it as the rim track of floors and rafters.

U – U-CHANNEL:

You can use U-channel for bridging, blocking, and custom applications. In addition, U-channel members do not have returns or lips.

F – FURRING CHANNEL:

Use Furring channels as purlins, bridging, and backing. Also, furring can be useful for framing suspended ceiling assemblies.

L – L-HEADER:

You can use L-headers in load-bearing wall framing as headers. When using L-headers, it eliminates the labor you need to field-assemble those headers.

How to Read the Numerics on Your CFS Designator Profile

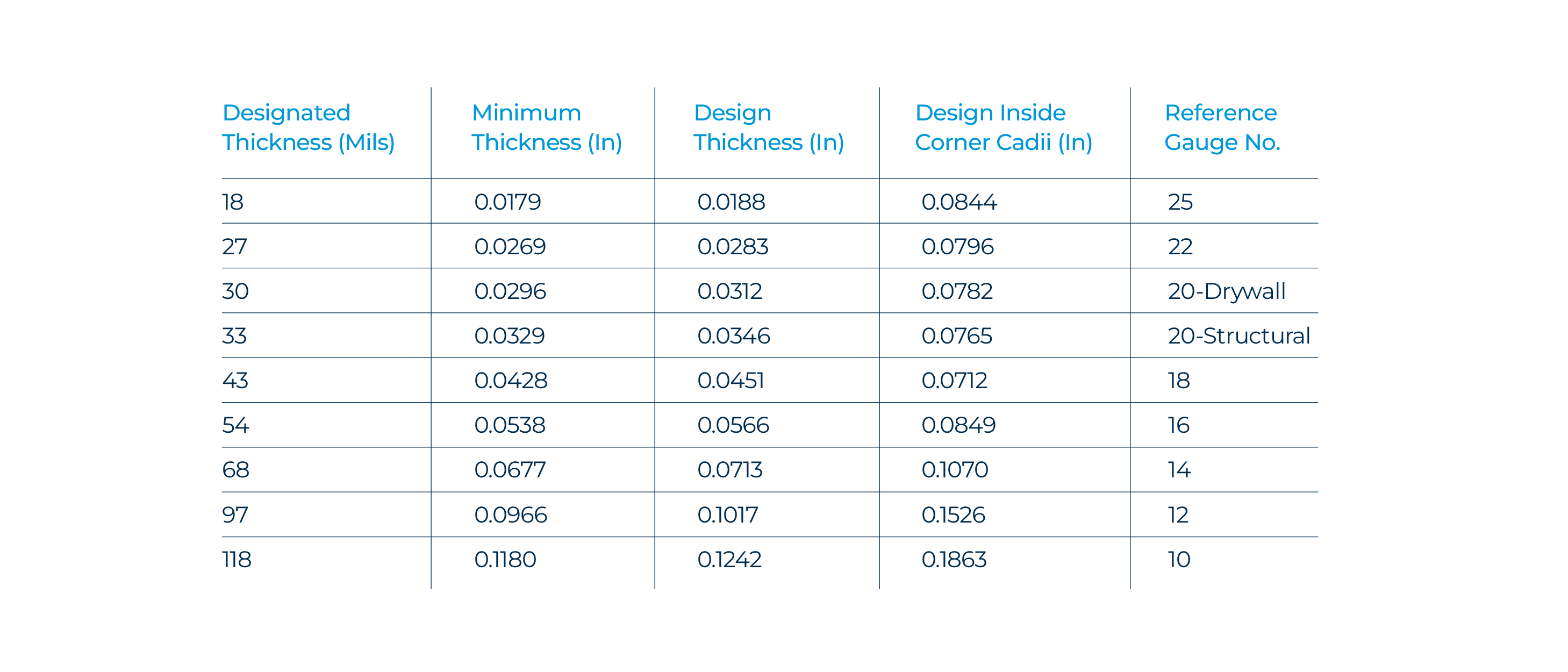

- Minimum thickness represents 95% of the design thickness. It is also the minimum acceptable for projects using section A2.4 of the AISI S100-07 with S2-10 Supplement.

- This table bases thickness on inside corner radii. Table courtesy of Steel Framing Industry Association.

With a foundational knowledge of the benefits, training options, and ordering process for CFS framing, you now have enough knowledge to move forward with your next project.

But if you still have questions, we can help. Whether you’re stuck in the design or planning process or would like ideas for reducing costs or speeding up construction, the MSS team of experts is here to help. We offer complimentary project assistance for new or existing CFS framing projects.

Let's Get Rolling!

Contact Us!

When you consider the entire lifecycle of a building, the use of CFS framing can offer significant cost savings. This is due to a decrease in labor, off-site construction, and long-term resistance to mold, vermin, and termites.

If you have an upcoming project and have specific questions, request assistance from the Modern Structural Systems team of experts.