Residential and Commercial Light Gauge

Cold Rolled Steel Joists

Manufacturing superior quality joists for use in building and construction projects across the southeast United States.

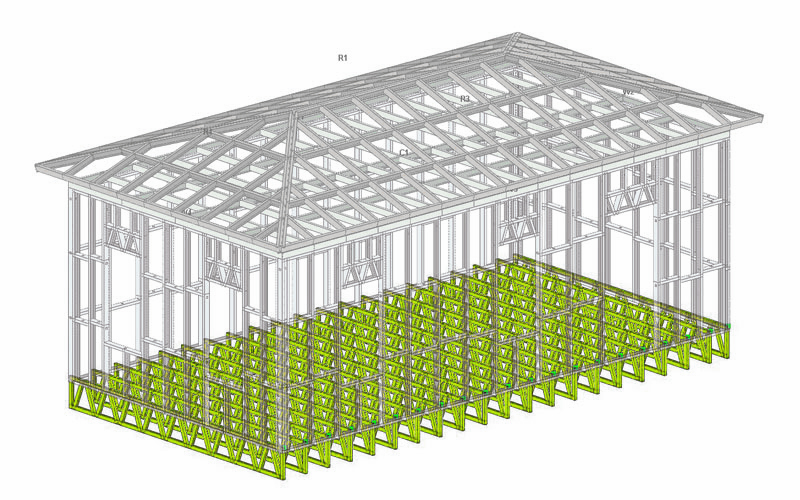

Joists are used as a rectangular horizontal framing member to span open spaces in ceilings, floors and roofs. They are commonly spaced at either 16”, 20”, or 24” apart. When spaced between walls they transfer the loads to the vertical members. Depending on the use the joists may be covered in sheathing or left uncovered to reveal open web bracing. Most often joists are often laid parallel to one another and either rest on top of walls or are connected via Simpson strong ties or other hangers.

Light gauge steel joists offer a greater value than wood or structural steel when you consider the total cost of the build.

Benefits of Light Gauge Steel Joists

When walking on a LGS (light gauge steel) joist you will notice the stiffness is much more apparent than wood.

• The reduced deflection of the cold rolled steel produces a product with more stability than wood.

• Because of the steel properties, there is no possibility of rotting, sagging, changing shape from temperature, and they are not susceptible to deterioration from organisms.

• Their galvanized or galvalume coating ensure the Modern Structural System’s joists have the strength to support a load over many decades, and out-perform nearly all the other alternatives in more extreme environments.

Transportation and Shipping

We work closely with several carriers with pre-negotiated rates to deliver your steel via flatbed trailers.

These will either be 18 wheeler 53’ trailers or gooseneck 40’ trailers. We don’t surprise you with hidden costs so we will include this shipping into your pricing estimations. When possible, we prefer to use the gooseneck trailers because the cost per mile is always less than larger trucks.

Your joists will be bound, stacked, and secured as densely as possible. Finally, because of the light weight of the joists themselves we will always “block out” the trailers volume before hitting the maximum weight limits. These weight to volume advantages encourage trucking companies to give us the best rates because fuel efficiency will be possible.

Joist Ordering Process

When ordering your joists our process is simple and straightforward:

• Simply submit your architectural drawings via our online system and our affiliated engineers will begin estimating the construction parameters.

• The designers use our 3D CAD software to draw your parts as components in your project for visualization and exact engineering.

• Because the cold formed steel weighs less than wood you are able to get higher performance than legacy wood methods.

• Next we will give you a price to produce your project and estimated timeline this is usually less than 14 days.

• The total cost (Including labor, waste disposal, other benefits) of the steel joist upgrade is almost always less than using wood and lasts much longer.

Because we stock thousands of feet of coil in 18 gauge or 20 gauge steel we are able to get started on your job quickly following the initial deposit.

• Following the production of your finished goods joists we will individually double check dimensions and photograph your order with your job number or invoice labeled in our yard.

• Once your joists are produced, and quality checked, with your final balance paid, they are loaded on a carrier who will transport them to your job site where they will be easily unloaded by hand or machine and erected as part of the project.

Example Joist Schedule